Choosing the correct trailer to carry aggregate at 44 tonnes on UK roads is both simple yet also a remarkably difficult. The UK uses a mixture of aggregate WALKING FLOOR® trailers, aggregate pushout trailers, aggregate insulated tipping trailers and then rigid tippers. There are multiple reasons why one type of trailer is preferred to another and particulary 'who' you ask in the supply chain for an opinion. For me the first constraint is the question do you want to avoid the hazard of tipping? Then 'can the aggregate material be tipped safely'? Is your profitability driven by payload? Clearly many other constraints join the mix - contract security, driver capability - need to be able to mix load types - aggregate with hardcore or muck away contracts.

Newton Trailers current first choice trailer for the transport of Aggregate is:

Recommended First Choice Trailer: Fliegl Aggregate Push Out Trailer or Push-Off Trailer Newton and Fliegl in Harmony

Recommended Second Choice Trailer: STAS Aggregate Tipping Trailer

Recommended Sales Options: Hydraulic Rear Door; Automatic Sheet System

Seasonal: No - a year round product!

Tascc Product: Yes and no. Virgin aggregates yes - recycled materials no.

Product Density: 2300 kgs/m3

Trailer Volume: 40 cuyd

150 millon tonnes of Aggregate Transported in the UK per annum.

A trend apparent in Aggregate Transport in Europe is that growing numbers of transport companies are switching from tipping trailers to pushout trailers. Eurovia and others use the Fliegl Aggregate pushout trailer extensively already in Europe. In the UK the tradition is to use 8 wheel rigids despite this having no logic. In Europe a rigid would be a non logical purchase due to massive payload and efficiency losses - in the UK these vast losses are buried in the confused politics of the 8 meter Bridge Formula and the broken links between engineering and transport companies - I am surprised they still dont use horse cart and a wooden wheel barrow - it would make as much sense. In the 2014 era Aggregate Trailers that use HORIZONTAL discharge became available - WALKING FLOOR® Trailers - such as the Titan WALKING FLOOR® we sold or the BMI WALKING FLOOR® trailer or the Wilcox WALKING FLOOR® Trailer. Many had dubious insulation and ridiculous running costs and largely have dropped out of favour - they sort of work but with vast capital input; huge depreciation; poor insulation; eyewatering running costs. Then Aggregate Belt loaders appeared on the scene in 2018 - mainly Fruehauf copying the Trout River of Canada product. These cure some of the problems of the floor but then have limited scope for use on a wider range of aggregates essential for the Holy Grail of 'backload' and what the owner must do when Aggregate is not running.

Now an existing product from Europe but new to the UK is available and is taking the market by storm. The Fliegl Aggregate Pushout or Ejector Trailer. It has all of the benefits of huge insulation to please the Engineer; massively improved payload over an 8 wheeler; horizontal discharge to satisfy health and safety; simplicity of design to decimate running costs and unlimited product restriction - so versatility of product from Aggregate to Muck away - de risking the purchase decision. It can be purchase slightly cheaper - about £5,000.00 or so less - if you take the uninsulated version for cold aggregate - but the weight and price penalty is low enough to default to a fully insulated product to get access to the higher rates offered to insulated trailers.

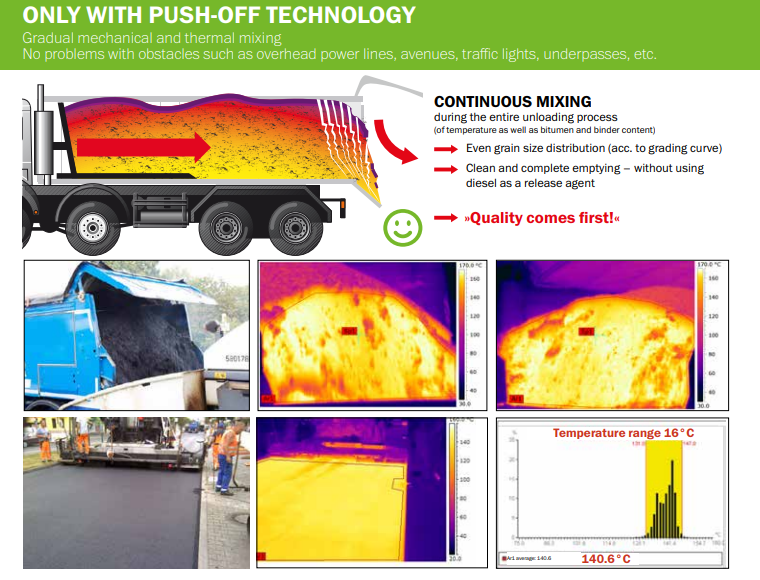

Asphalt is an aggregate base with bitumen and other addititives plus TEMPERATURE. Cooking 27 tonnes of stone to 180 degrees and then pouring bitumen on it requires a simply staggering amount of costly energy. The product will drop out of conformity depending on the specification below 120 degrees. Wasting 60 degrees in the transport phase is simply no longer acceptable to industry. The Fliegl Asphalt trailer is super insulated with high quality polyisocyanurate insulation and careful attention to thermal bridging makes the Fliegl simply amazing. In Germany they even use the trailers as over flow stores when batch manufacturing Asphalt. The Fliegl has the added benefit of mixing the heat creating homogeniety at time of discharge. This is proven in numerous engineering papers in Germany and Austria to improve the road construction. In the UK using insulated tipping trailers and insulated rigid tippers creates systematic cool spots in the road at the time of lay which swiftly become rumble strips and premature road failures. If deployed correctly the Fliegl can allow the use of Warm Asphalt and also allows road laying into the colder months.

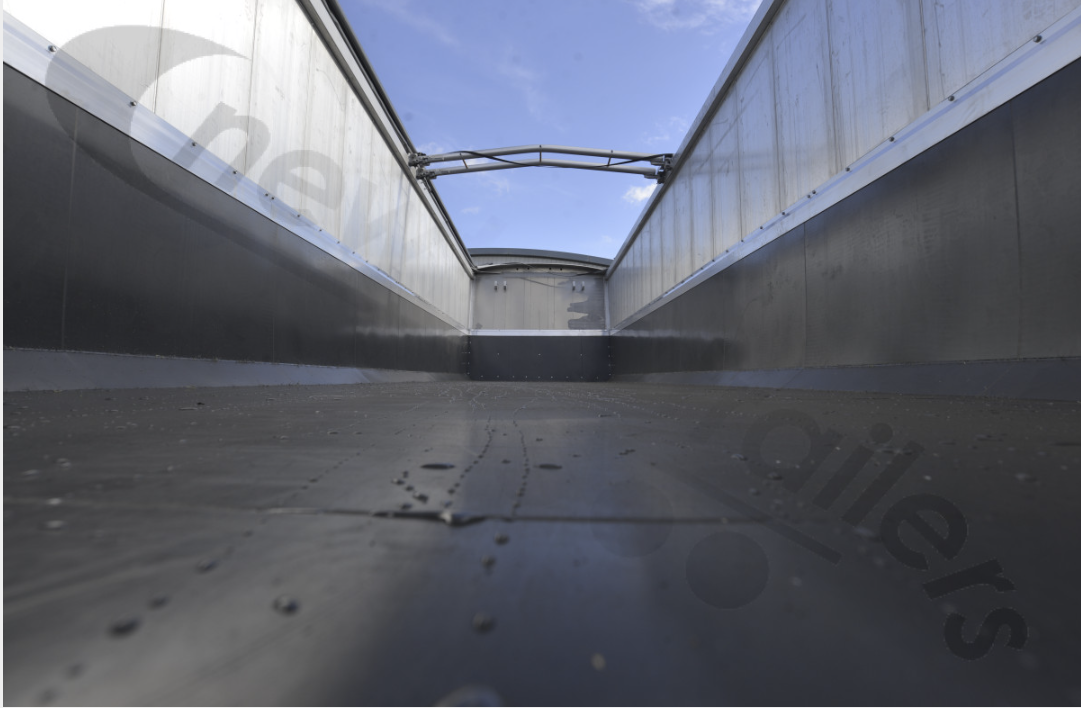

The joy of the Fliegl is that when not laying Asphalt the 5 mm Hardox steel box can be used on plannings and other aggregates up to Muck Away and Skip Wastes. This de-risks the utilisation dilemna for the sub - contractor. When the black top is not running the owner can utilise the trailer on any other work - lime into fields or skip wastes. Always a back load. This is not possible in alloy body tipping trailers, moving floors or belt loaders. Versatility generating profits.

Newton have worked in partnership with VWS and can provide digital information of the Aggregate temperature in the box - or a good enough range to make sensible utilisation information. We take the temperature inside the box in 2 (or more) places and send it to a signal on the trailer - red amber green. When red the aggregate is out of conformity and should not be used. Green is go. The temperature is logged and accessible on free remote monitoring software and on the drivers handheld. A company can monitor location +/- 10 meters, what mass of payload is on the trailer, view pictures of the load inside; and get REAL TIME temperatures +/- 10 degrees to make operational decisions. This means if there are 4 trailers on site the operator would logically use the coolest trailer first. This will prevent poor performance of aggregate surface and maintain that costly element is still present in the product when it is laid. No other trailer combination can do this in the UK. Clever team here at Newton!! In time and with learning a fleet of these trailers may allow the cook temperature of a large batching plant to be turned down say 10 degrees and still achieve safe product conformity at the point of lay.

Careless talk costs lives. Tipping in a rigid or a tipping trailer using gravity to move the load introduces a hazard into the operation of aggregate transport. This hazard can be avoided using horizontal discharge trailers. Many hundreds of rigids and trailers tip over per annum with all the dangers and costs this incurs. It is best to avoid using a large bulker to carry aggregates as the potential for mis loading is introduced. All tipping should really ocurr on prepared level ground with an aggregate that can be tipped - not sticky, wet or mis loaded up one side. There are two 'standards' that a rigid or trailer can be aligned with DIN70073 or ISO 22138, then there are some IRTE 'Guidelines' that are controversial. Tyre type and construction, tyre pressure, suspension type, suspension make; chassis design; cylinder type and manufacturer; body design, type, size material; length; sheet type, open closed; door type; center of gravity of load; stickyness all need to be computer modelled - homologated and then tested. Despite many claims in the UK almost none of this is done completely and compelingly despite well publicised marketing claims to the contrary. The last public tilt test center in the UK closed in 2018...... so how many UK Manufacturer's have their latest trailers tilt tested with all the latest axles, tyres etc - ask them to justify in detail and you will find mostly ghosts of trailers tested 20 years ago - if that?

Aggregate Song: insert MP3 here.

Aggregate Trailer Option: VWS Newton Weigher with inclinometer and body camera.

Aggregate Trailer Option: Powered rear under run bar. Lifts up out of the way of the Aggregate Road Laying Paver.

Aggregate Trailer Option: Powered rear door on an insulated tipping trailer. Powered doors are simpler and get out of the way of the operation without getting a driver or banksman's hands dirty.

Aggregate Trailer Option: Quicksilver 12 mm liner on a tipping trailer. For hot product only the 12mm is strong enough. Prevents sticking of the product and tip overs. It does also provide some extra insulation for temperature purposes. Downside ££££ and KGS.

Newton Trailers are the largest supplier of Tipping Trailers, Ejectors and Moving Floors in the UK. Although for Aggregate transport we would say that the Fliegl Pushout has no comparable product as you get 27 tonne payload without tip over risk there are customers who prefer to use tipping trailers. These will generate a payload gain but come with the hazard of stability in use. We would recommend either the insulated STAS aluminium aggregate trailer from Newton Trailers 01525 872466 or the more interesting STAS U Rockstar insulated Aggregate Trailer. Both trailer types come in uninsulated form. Aggregate tipping trailers can generate a 30 tonne payload which is 10 tonnes more than a rigid tipper.

If you really are weird and bored you could try listening to our aggregate trailer song:

If you really enjoy your work and love our trailers then you could indulge yourself or perhaps that special person in your life with a sugar beet T shirt. Follow the link: CLICK HERE

Now this was a bit of debate here at Newton Headquarters what recipe to go with Lava Cake? Rocky Road? or Baked Alaska, or Tarmac Road Cake- in the end we went with: CLICK HERE

| Best Match | Options | Volume | Payload | |

|---|---|---|---|---|

| New | STAS Aggregate Tipping Trailer | Quicksilver Liner - "Buildstar X" 10mm Quicksilver Liner - "Agrostar" 10mm Lights LED Strobe (Pair) Quicksilver Liner - "Agrostar" 12mm WABCO TX-Trailer Pulse EBPMS WABCO Brake and Trailer Monitoring Subscription £10.00+VAT per months for 36months Quicksilver Liner - "Buildstar X" 12mm |

41 CuYds (31.3m3) | 30050kg |

| Used | 2015 Benalu Aggregate Tipping Trailer | 40 CuYds (30.6m3) | 30550kg | |

| Also See | 2019 Fruehauf Aggregate Tipping Trailer | Quicksilver Liner - Halfpipe 10mm Side Guard Infill Panel (Painted) Lights LED Strobe (Pair) Lights Side Marker Flashing Indicators Quicksilver Liner - Halfpipe 6mm Quicksilver Liner - Halfpipe 12mm |

39 CuYds (29.8m3) | 30040kg |

| Also See | 2014 Muldoon Plank Sided Tipping Trailer | WABCO TX-Trailer Pulse EBPMS WABCO Brake and Trailer Monitoring Subscription £10.00+VAT per months for 36months |

70 CuYds (53.5m3) | 30000kg |

| Also See | 2022 STAS Plank Sided Tipping Trailer | Quicksilver Liner - "Agrostar" 10mm Lights LED Strobe (Pair) Quicksilver Liner - "Agrostar" 12mm WABCO TX-Trailer Pulse EBPMS WABCO Brake and Trailer Monitoring Subscription £10.00+VAT per months for 36months |

71 CuYds (54.3m3) | 29750kg |

| Also See | 2022 STAS Plank Sided Tipping Trailer | Quicksilver Liner - "Agrostar" 10mm Lights LED Strobe (Pair) Quicksilver Liner - "Agrostar" 12mm WABCO TX-Trailer Pulse EBPMS WABCO Brake and Trailer Monitoring Subscription £10.00+VAT per months for 36months |

71 CuYds (54.3m3) | 29750kg |

| Also See | 2021 STAS Plank Sided Tipping Trailer | Quicksilver Liner - "Agrostar" 10mm Lights LED Strobe (Pair) Quicksilver Liner - "Agrostar" 12mm WABCO TX-Trailer Pulse EBPMS WABCO Brake and Trailer Monitoring Subscription £10.00+VAT per months for 36months |

71 CuYds (54.3m3) | 29750kg |

| Also See | 2015 Fruehauf Plank Sided Tipping Trailer | Lights LED Strobe (Pair) Lights Side Marker Flashing Indicators |

70 CuYds (53.5m3) | 29700kg |